Application of Hook and Loop Sanding Disc

|

Item |

Recommand Grit Range |

Work Process |

|

Coarse (40#-150#) | .Poly-putty grinding |

| .Remove paint | ||

| .Automotive putty grinding | ||

| .Wall putty grinding | ||

|

Medium& Fine (180#-2000#) |

.Primer/Base coat grinding | |

| .Paint surface grinding | ||

|

|

40#-600# |

.Hardwood grinding |

| .Grinding of automotive body sheet metal parts | ||

| .Metal grinding | ||

| .Plastic grinding |

Item No.: KD8110

|

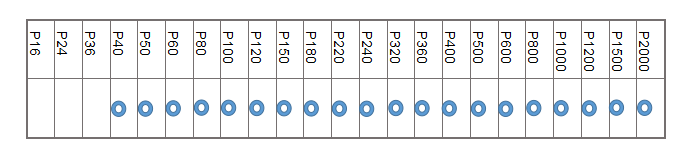

Grain |

Base |

Coating |

Size |

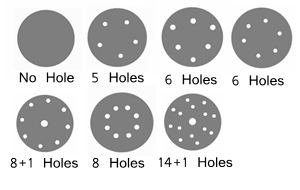

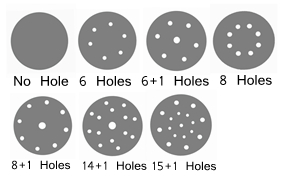

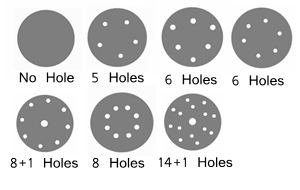

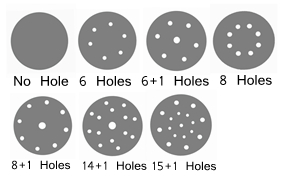

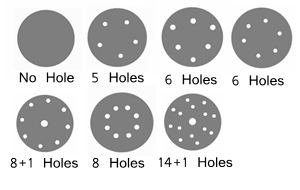

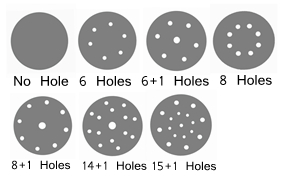

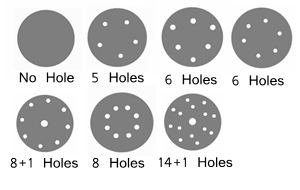

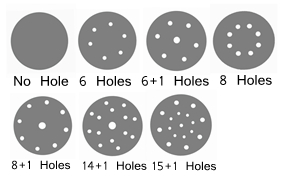

Availabel Holes |

| A/O | Film | Open Coated/Special Coated | 2"/3"/4"/4.5"7"/9"/12" |

|

|

Open Coated Special Coated |

5" |

|

||

| 6" |

|

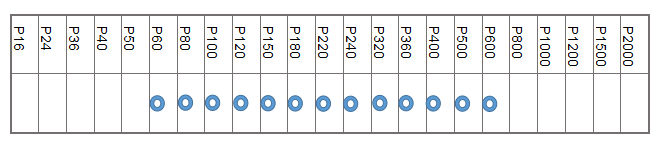

Main Grit

Item No.: KD8120

|

Grain |

Base |

Coating |

Size |

Availabel Holes |

| A/O |

D-weight Paper E-weight Paper |

Semi-Open Coated Special Coated |

2"/3"/4"/4.5"7"/9"/12" |

|

|

Semi-Open Coated

Special Coated |

5" |

|

||

| 6" |

|

Main Grit

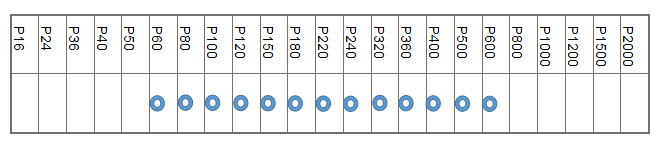

Item No.: KD8130

|

Grain |

Base |

Coating |

Size |

Availabel Holes |

| A/O |

D-weight Paper

|

Semi-Open Coated Special Coated |

2"/3"/4"/4.5"7"/9"/12" |

|

|

Semi-Open Coated

Special Coated |

5" |

|

||

| 6" |

|

Main Grit

Item No.: KD8140

|

Grain |

Base |

Coating |

Size |

Availabel Holes |

| A/O |

D-weight Paper E-weight Paper

|

Semi-Open Coated |

2"/3"/4"/4.5"7"/9"/12" |

|

| Semi-Open Coated | 5" |

|

||

| 6" |

|

Main Grit

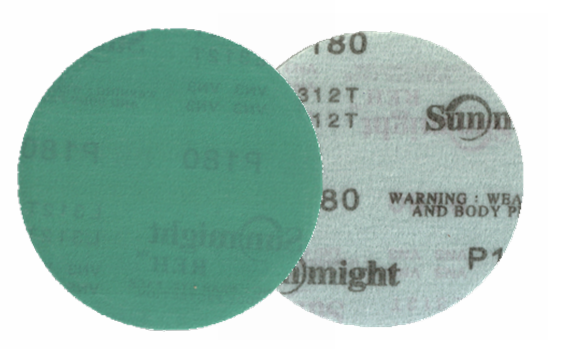

Abrasvies Grain: Aluminum Oxide

Applications: Ideal for woodworking, metal finishing, and for plastic like materials.

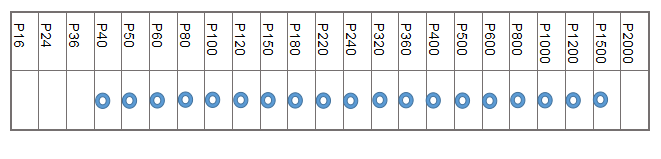

General Application of Grit

|

Grit |

Spec. |

Applications |

|

60#80# |

Coarse |

For removal and leveling of moderate surface imperfections |

|

100#120# |

Medium |

For smoothing and light removal on bare surfaces |

|

150#180# |

Fine |

For bare surface cleaning and finishing |

|

220#240#320#400# |

Very Fine |

For primer and sealer sanding, and other very fine sanding of bare surfaces. |

|

600#800#1000#1500#2000# |

Extra Fine |

Between coatings, primer and sealer sanding |

Recommended Sanders for 5" Hook & Loop Disc

Applicable Industries:

■ Chemical and processing industries ■ Fitting and container construction

■ Steelworks ■ Foundries ■Tool and mould construction

■ Pipeline construction ■Dockyards ■ Automotive industry

■ Steel construction, locksmiths

■ Aviation and aerospace, gas turbine construction and repair

■ Machine engineering

Introduction for Abrasives :

A/O: Alumimun Oxide

Aluminum Oxide grain which has high efficiency grinding performance. Cotton cloth base synchronous consumption fast, does not burn the workpiece.Glassfiber backing and plastic backing available.

With efficient grinding and polishing effect, the product is windly applied in the metal, stainless steel, wood, etc

C/O: Ceramic Oxide

With high quality ceramic grinding grain, which can quickly and efficiently finish the surface treatment of the workpiece. It has excellent effect for polishing the stainless steel.Glassfiber backing and plastic backing available.

Z/A: Zirconia Alumia

For grinding the stainless steel workpiece, the zirconia grain with outstanding effect and high efficiency. In addition to stainless steel, it is also used for the metals.Glassfiber backing available.

Instructions:

1. Please try to choose operation indoors environment which without clutter phenomenon. The user should also concentrate on the operation to avoid an accident. If use it at outdoor, try to choose a quiet environment.

2. During the grinding process, the workpiece should be kept parallel to the working water level.

3. The user's power should be evenly distributed when operation. Never suddenly heavy and lightly.

4. Avoid moving or slipping the workpiece during grinding.

Warning:

1. Must wear dustproof mask and goggles when working.

2. Never exceed the maximum safe speed.

3. Discs must be mounted correctly and used with metal guards and goggles.